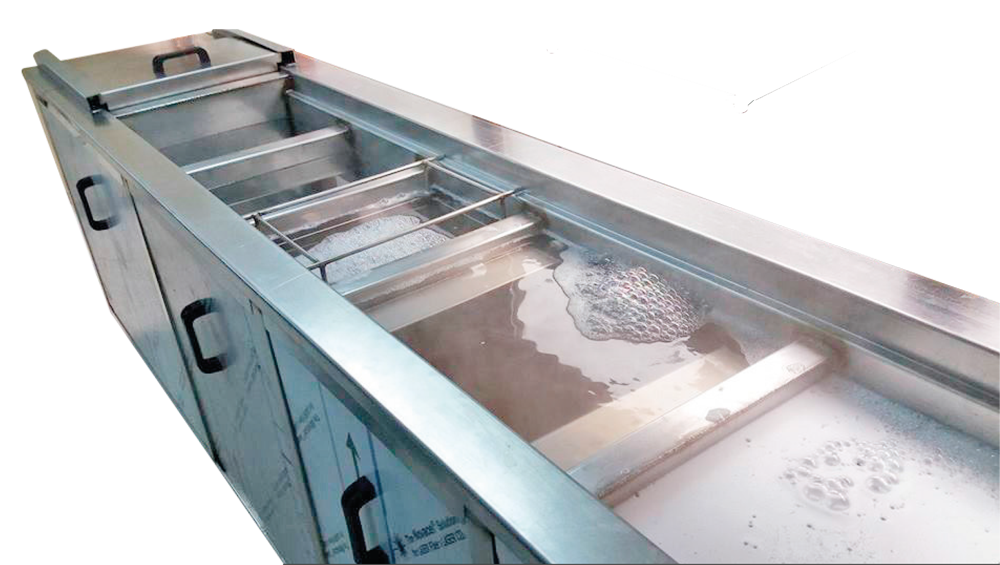

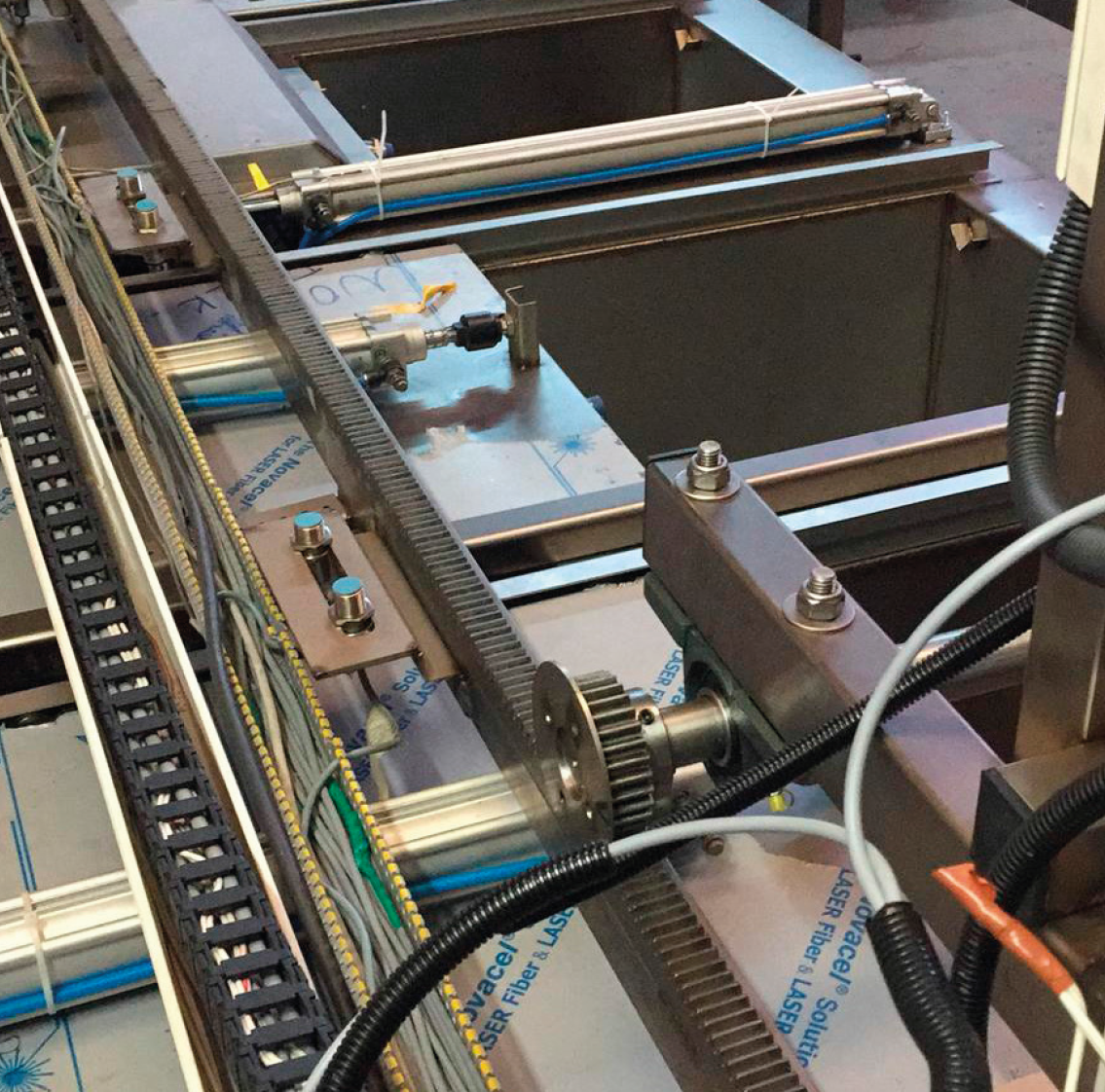

Tailored to meet the robust cleaning requirements of industrial settings, Industrial size ultrasonic cleaners are the epitome of efficiency in handling demanding cleaning tasks. Specifically crafted for industrial applications, these high-capacity cleaning machines demonstrate exceptional performance and reliability.

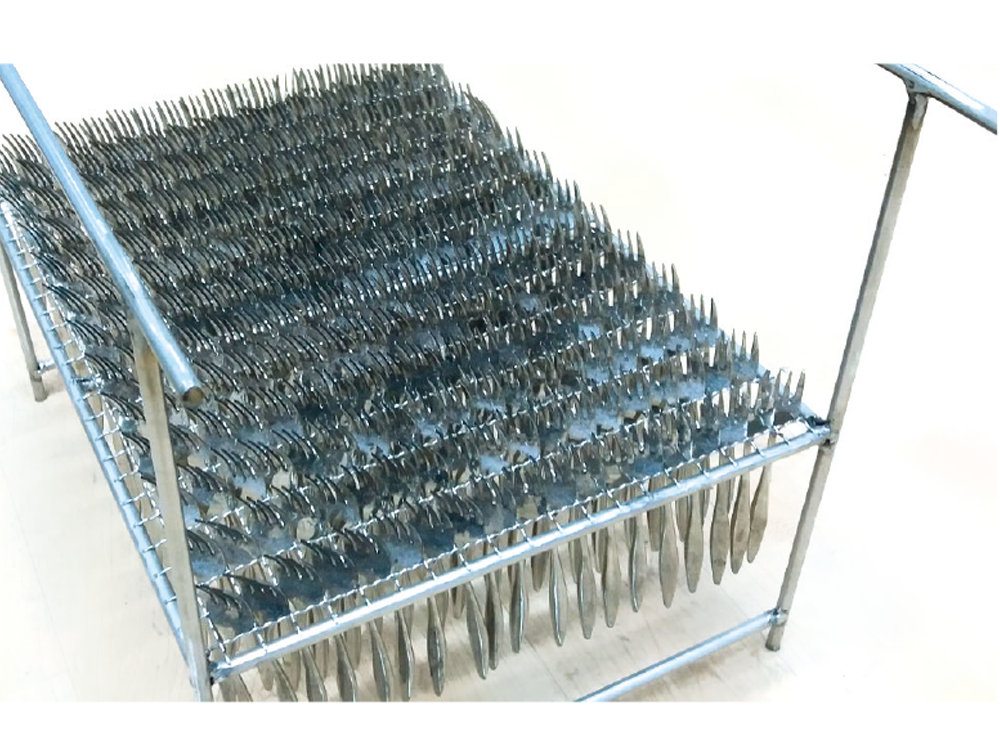

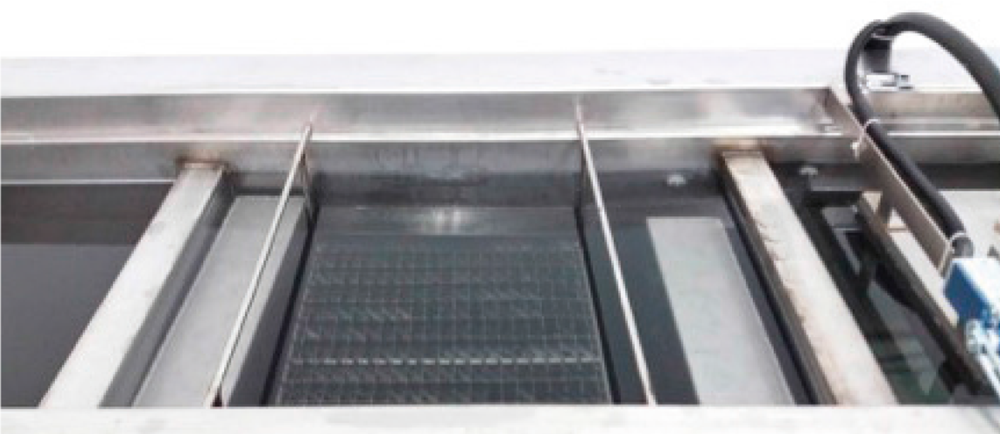

Designed to confront the most challenging cleaning tasks, these industrial-size ultrasonic cleaners distinguish themselves by effortlessly handling substantial workloads. Whether grappling with stubborn contaminants, intricate components, or extensive surfaces, these specialized cleaners guarantee optimal results.

The adaptability of industrial ultrasonic cleaners spans across various industries, encompassing manufacturing, automotive, aerospace, and more. Their precision and effectiveness render them indispensable for upholding the highest cleanliness standards in diverse industrial processes.

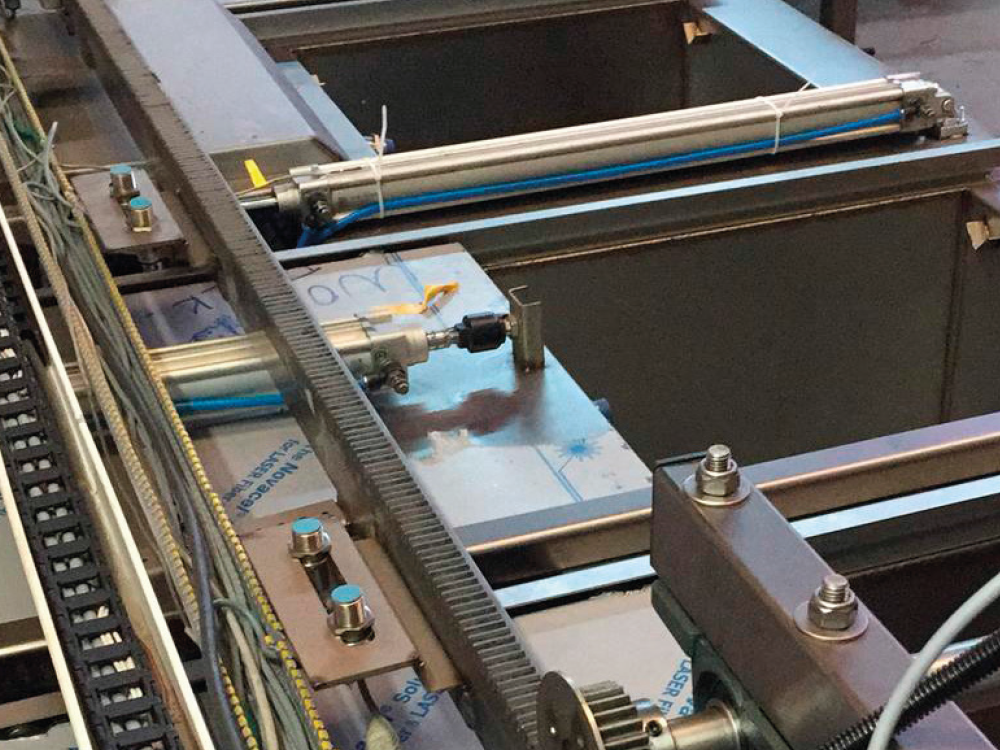

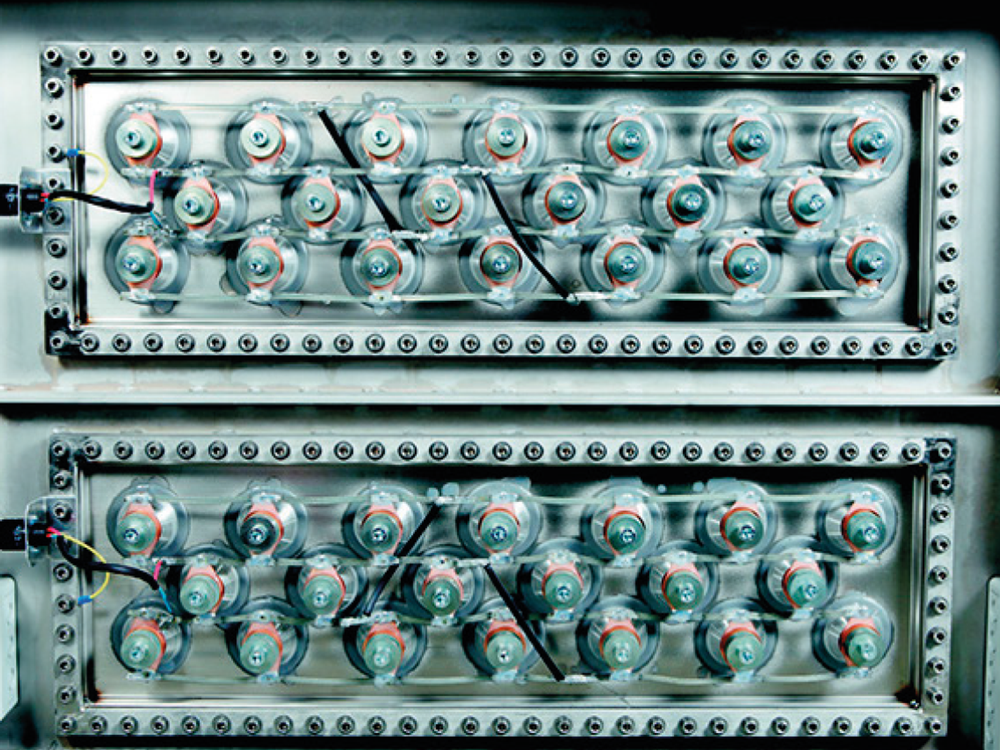

Harnessing state-of-the-art technology, these cleaners leverage ultrasonic waves to achieve thorough and consistent cleaning. This cutting-edge cleaning method ensures a profound and all-encompassing cleansing process, fostering efficiency and productivity in industrial operations.

Opting for Industrial size ultrasonic cleaners is a strategic decision for businesses seeking a dependable and high-performance cleaning solution. Elevate your industrial cleaning processes with these advanced devices, meticulously tailored to meet the distinctive demands of heavy-duty applications, thereby ensuring impeccable cleanliness and operational excellence.