KAYAKOCVIB: Your One-Stop for Deburring, Surface Finishing, and Polishing Solutions

At KAYAKOCVIB, we understand the importance of a flawless finish. That’s why we’re proud to offer a comprehensive range of deburring machines, surface finishing machines, and polishing machines that deliver exceptional results for a wide variety of applications.

Deburring Made Easy:

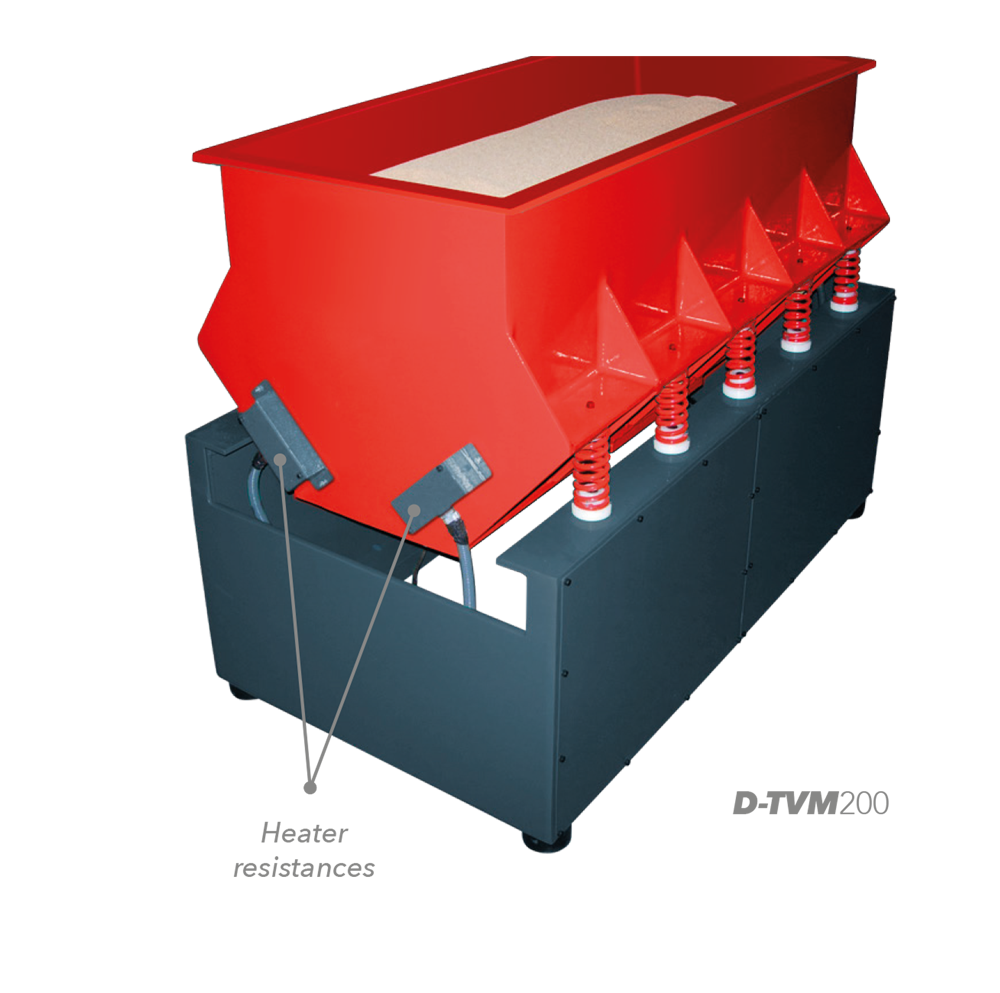

Our high-performance deburring machines remove burrs and sharp edges efficiently, ensuring your parts are safe and ready for further processing. Choose from various models, including our popular KVM series, designed for precise deburring and minimizing surface roughness.

Achieve a Flawless Finish:

For superior surface finishes, look no further than our top-of-the-line surface finishing machines. With innovative technologies and customizable options, we can help you achieve the perfect finish for your specific needs. Whether you require a uniform texture, a mirror-like shine, or a specific surface profile, our machines can handle it all.

Unleash the Shine:

Our polishing machines are designed to bring out the brilliance in your metal and non-metal parts. From delicate jewelry pieces to industrial components, our equipment delivers a consistently smooth and polished finish that enhances both appearance and functionality.

Why Choose KAYAKOCVIB?

When you choose KAYAKOCVIB, you’re not just investing in machines; you’re investing in quality, performance, and expertise. Here’s what sets us apart:

- Unwavering commitment to quality: We use only the finest materials and components to ensure our machines deliver long-lasting performance and reliability.

- Expert design and engineering: Our team of talented engineers constantly innovates to create cutting-edge machines that meet the evolving needs of our customers.

- Unparalleled customer service: We’re dedicated to providing our customers with the support they need to maximize their investment in our equipment.

Ready to Experience the KAYAKOCVIB Difference?

Contact us today to discuss your specific requirements and discover how our deburring, surface finishing, and polishing machines can help you achieve exceptional results. We’re confident you’ll be impressed with our commitment to quality, performance, and customer satisfaction.