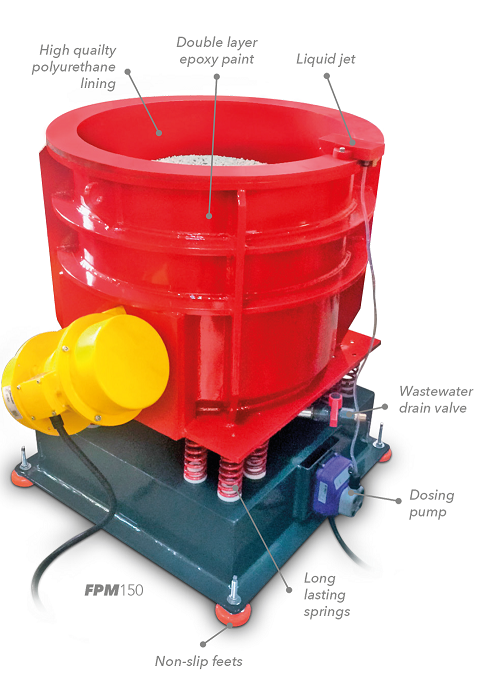

Step into the future of automotive aesthetics with our cutting-edge FPM Series Wheel Rim Polishing Machines, specifically the FPM150 model. Embraced by the automotive industry, these state-of-the-art machines have become indispensable for achieving impeccable wheel cleanliness and a dazzling polished finish.

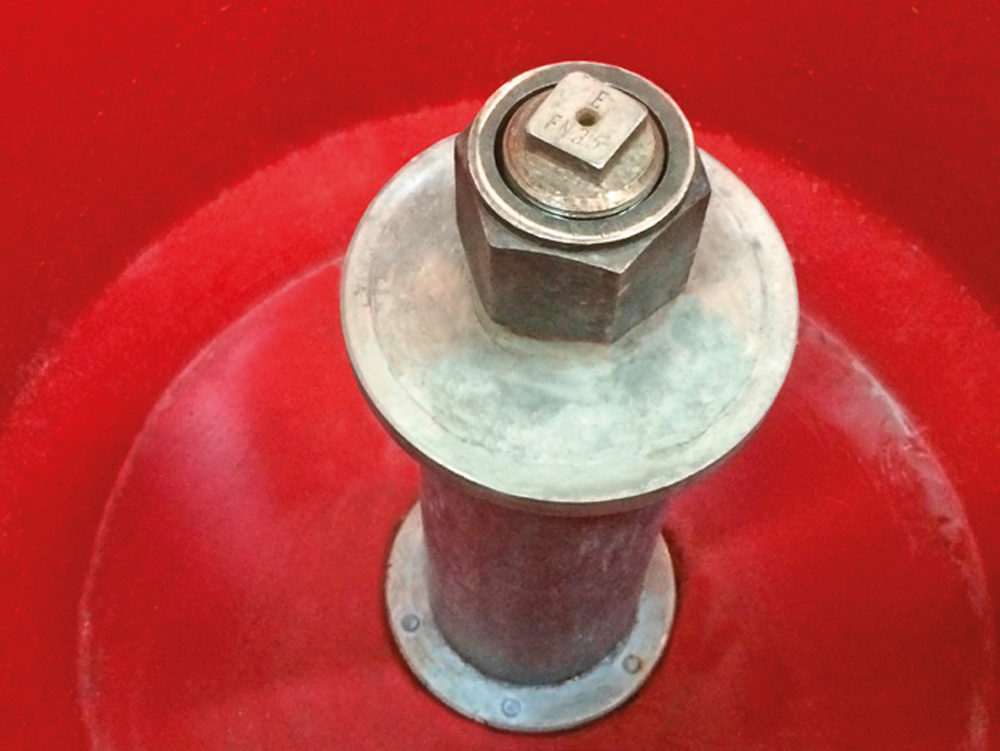

Engineered for excellence, our Wheel Rim Polishing Machines are meticulously designed to address various concerns within the automotive sector. From the precise grinding of fine scratches to the transformative art of polishing, and the effective removal of surface roughness, our machines redefine the standards of wheel maintenance.

In the fast-paced world of automotive innovation, the FPM Series stands out as a beacon of quality and performance. Elevate your wheel care routine with these machines that seamlessly blend efficiency and precision. Trust in the reliability of our FPM Series as it continues to make waves in the industry, setting new benchmarks for Wheel Rim Polishing Machines.

Discover the perfect synergy of technology and craftsmanship, ensuring that your wheels not only meet but exceed the expectations of automotive enthusiasts and industry professionals alike. Welcome to a new era of wheel rim cleaning and polishing excellence with our FPM Series.