Although there is no screen belonging to KSM series, SM coded vibrating screens are integrated into KSM series. The separator machines are useful for separating chips and products.

Series KSM Centrifugal Disc Finishing Machines

YOU CAN CONTACT US FOR DETAILED INFORMATION.

PARTS OF THE VİBRATORY DRAYER MACHİNG

Details of the KSM Series Vibratory Dryer Machines

The speed of processing is 10 times faster than vibratory bowls

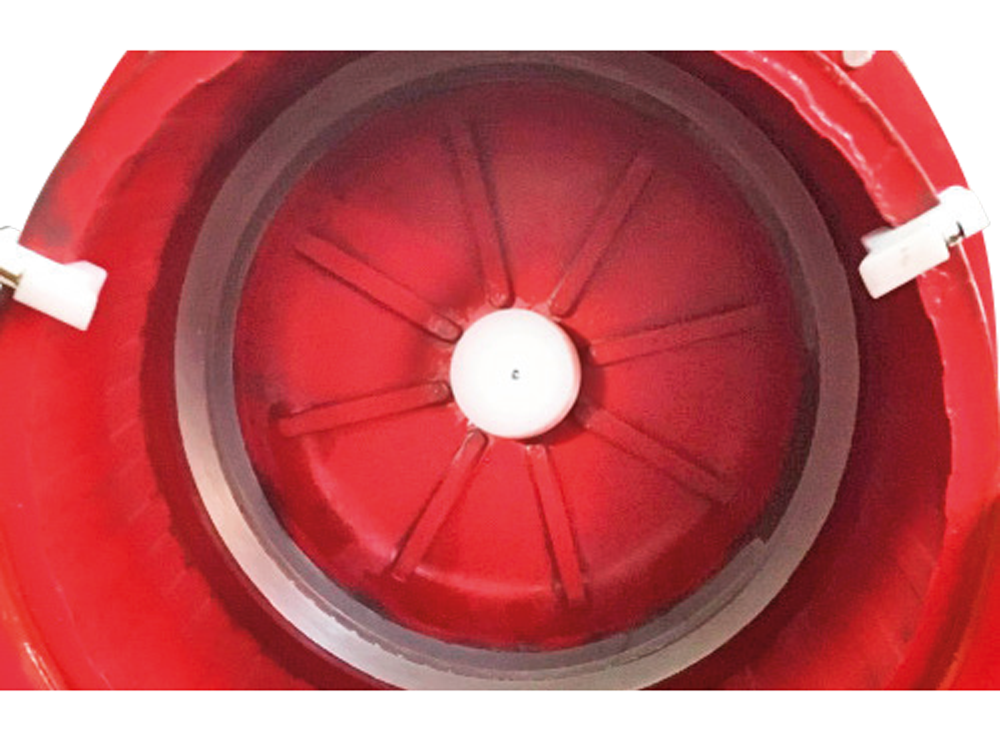

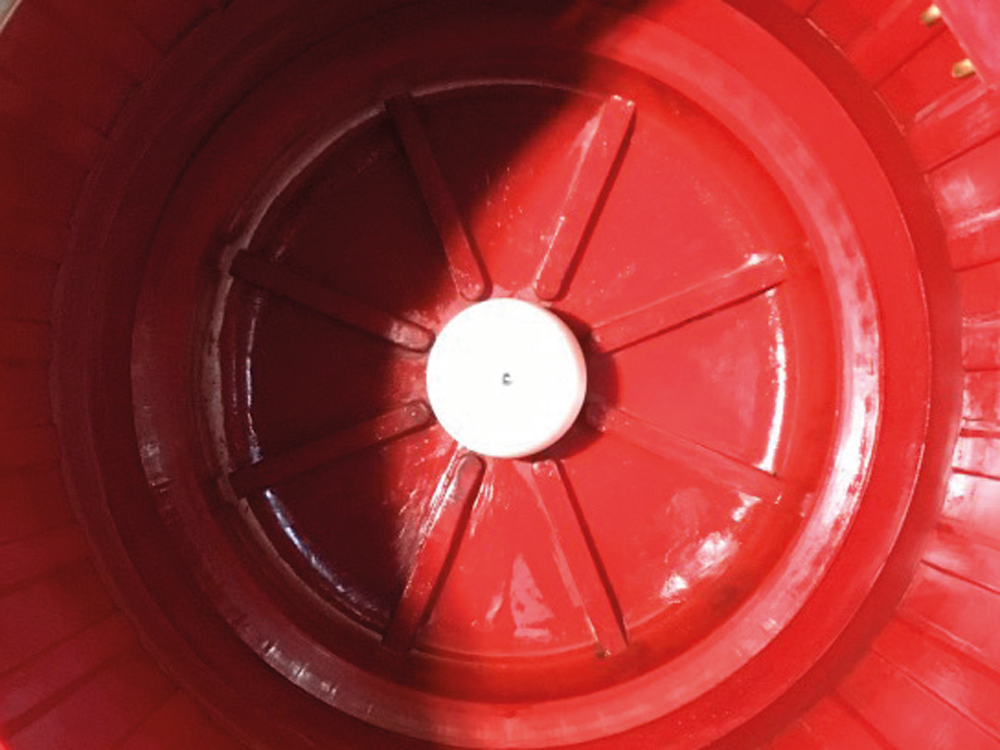

Our centrifugal bowls are produced as hardened aluminum casting and provide ease of unloading thanks to their light alloy.

Our high-volume bowls are easily unloaded with standard reducer

Unloading is optional in low-volume bowls.

The housing is insulated against water or corrosion.

Resistance to acidic environments with double layer epoxy paint.

The basin and bowl gap is designed in the most suitable way and the VORTEX effect allows fast processing.

Minimized service and spare parts costs thanks to the longlasting basin-bowl gap.

The parts can be separated by the sieve after deburring or polishing process. The separator is manufactured for KSM series and sieve plates can be changed to fit the required dimensions.

All centrifugal finishing machines have standard electrical box, equipped with time control, speed control unit.

All parts used in our machines are selected according to EU standards.

FOR DETAILED INFORMATION, YOU CAN CONTACT US ON WHATSAPP.

Series KSM Centrifugal Disc Finishing Machines

SSM

SM 18

SM 60

KSM Series Product Specifications

| Description | KSM 18 | KSM 60 | KSM 160 | |||||

| Working bowl gross volume (lt) | 21 | 63 | 179 | |||||

| Diameter of working bowl (mm) | 340 | 520 | 750 | |||||

| Engine power (kW), 380V / 50Hz | 0,75 | 2,2 | 5,5 | |||||

| Engine (RPM) | 1500 | 1500 | 1500 | |||||

| Dosage pump (5 lt / 7bar) | Standart | Standart | Standart | |||||

| Weight (kg) | 70 | 110 | 200 | |||||

| Unloading system | Manual | Manual | Manual | |||||

FOR DETAILED INFORMATION, YOU CAN CONTACT US ON WHATSAPP.

Our recommendations for KSM Series

SEPERATOR MACHINES

Although there is no screen belonging to KSM series, SM coded vibrating screens are integrated into KSM series. The separator machines are useful for separating chips and products.

CIRCULAR TYPE OF DRYERS

Circular Type of Dryers series round vibratory dryer machines are used to remove water from the surfaces of products that are wet after deburring or polishing processes and to improve their corrosion resistance.

YOU CAN CONTACT US FOR DETAILED INFORMATION.

ACCESORIES

Sound Cover

Automatic tilting

Automation board