Blank Coin Polishing System, BCP Series

YOU CAN CONTACT US FOR DETAILED INFORMATION.

Coin washing and polishing process

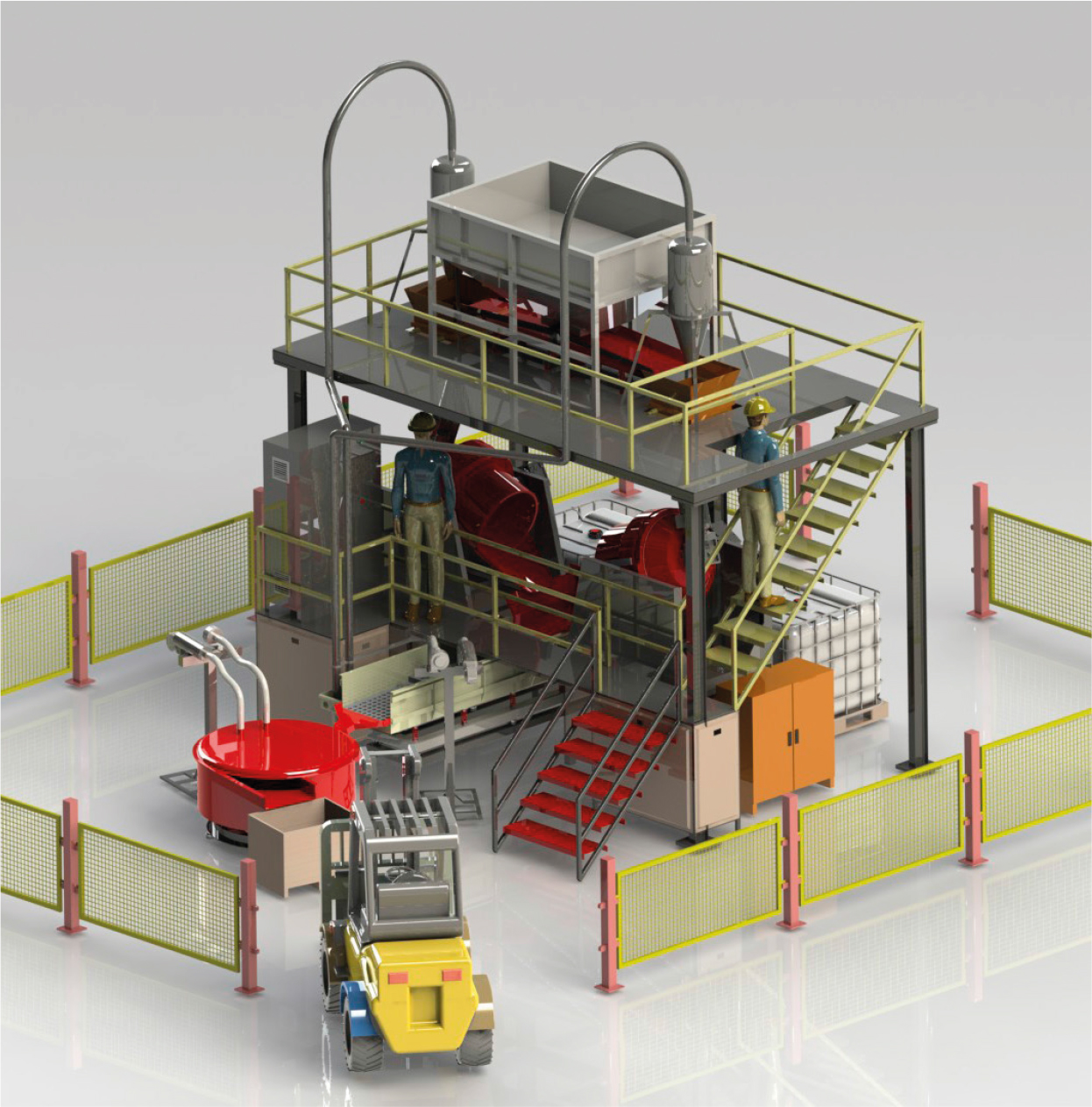

Introducing the revolutionary BCP Series, Blank Coin Polishing System, designed to elevate the coin manufacturing process to new heights. Our cutting-edge centrifugal washing machine swiftly and seamlessly eradicates stains, marks, and scratches from the surfaces of freshly baked washers. Crafted with a superior dubplate and ring construction, this system ensures a thorough cleanse, leaving your washers pristine without any damage and minimizing waste.

Whether you opt for a fully automatic, semi-automatic, or manual configuration, our coin-washing lines offer unparalleled efficiency in the polishing process. The BCP Series guarantees a flawless finish, contributing to the overall enhancement of your coin production. Experience the innovation that defines coin surface treatment, achieving a rapid and impeccable shine with our specialized fluids.

Step into the future of coin manufacturing with the Blank Coin Polishing System and witness a transformative approach to cleanliness and brilliance. Elevate your production capabilities with a state-of-the-art Coin Washing Machine, setting a new standard for quality and efficiency in the coin fabrication industry.

INFORMATION ABOUT THE PROCESS

In washing systems, the coins are loaded into the main coin silo via the loading conveyor. They are transferred to the weighing pan by the washer feeding vibrators in the silo. When the transferred washers reach the desired weight, they are taken into the centrifugal washing machine. The coins washed with PLC control are transferred to the separator; they are dried in the dryer after sieving and the process is completed. The prescribed amount of liquid and water is supplied to the system automatically and controlled by the water flow sensor. The system can be followed with PLC system software. 16 different programs can be installed according to the size of washers. Time-liquid-water use can be programmed as required. Optionally, the pH graph can be taken at the end of each process.

FOR DETAILED INFORMATION, YOU CAN CONTACT US ON WHATSAPP.