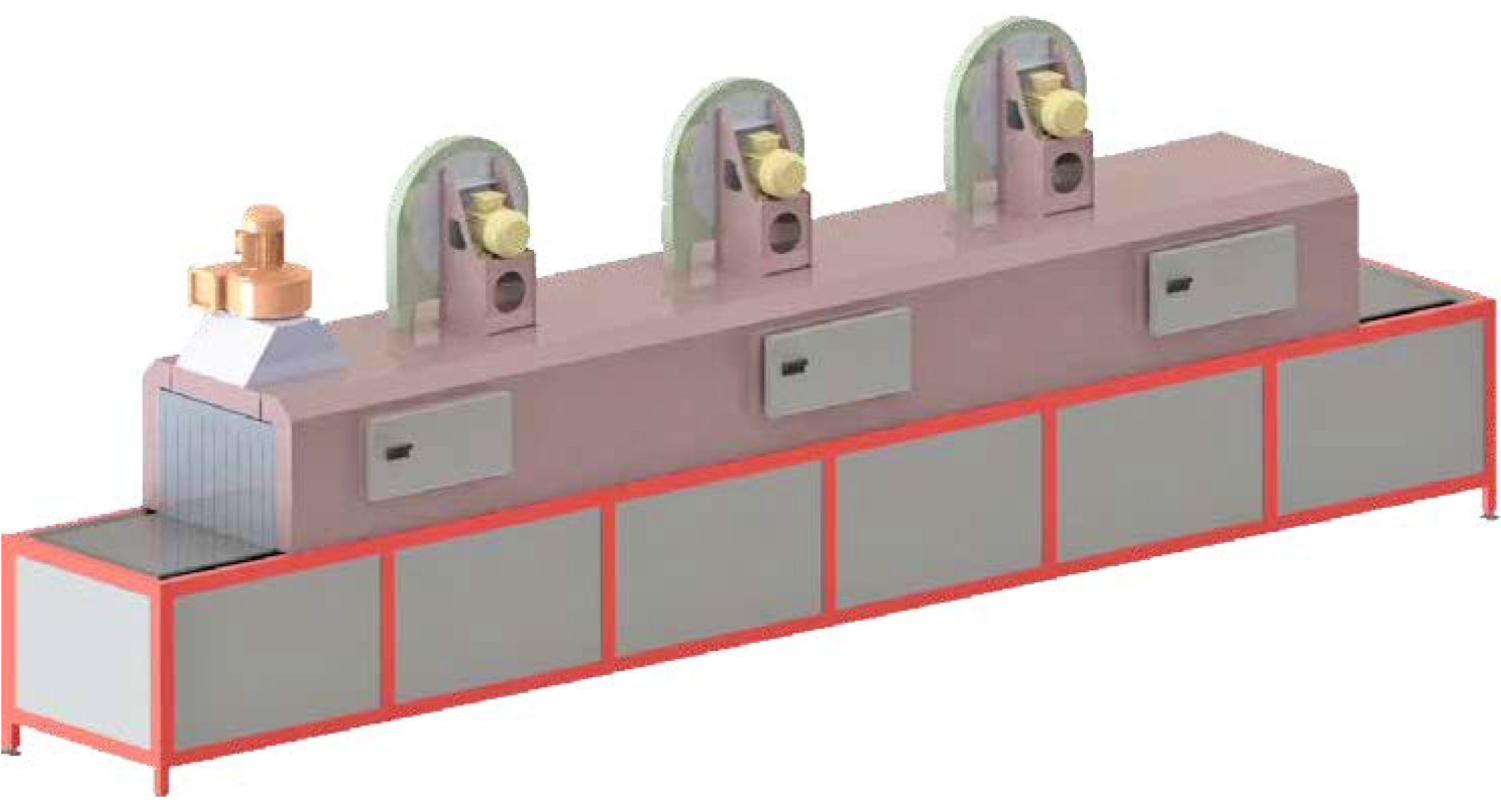

The T-DRY series introduces an innovative line of Tunnel Dryer Machines, meticulously crafted for diverse production needs. Tailored to accommodate various materials, product characteristics, and drying rates, these specialized machines play a pivotal role across a myriad of industries. Specifically designed to counteract water stains arising from surface treatments or other processes, Tunnel Dryer Machines find widespread application in ensuring the pristine quality of wet products.

In the food industry, their significance is underscored as they effectively combat the formation of harmful bacteria and fungi induced by moisture. The T-DRY series emerges as a solution to uphold product integrity and safety. Beyond their moisture-eliminating capabilities, these machines contribute to the packaging readiness of the processed items, further streamlining the production workflow.

The versatility of Tunnel Dryer Machines renders them indispensable in addressing the unique drying requirements dictated by the nature of materials and the intricacies of each product. Elevate your production processes with the T-DRY series, where cutting-edge technology meets the demands of precision drying across diverse industrial landscapes.