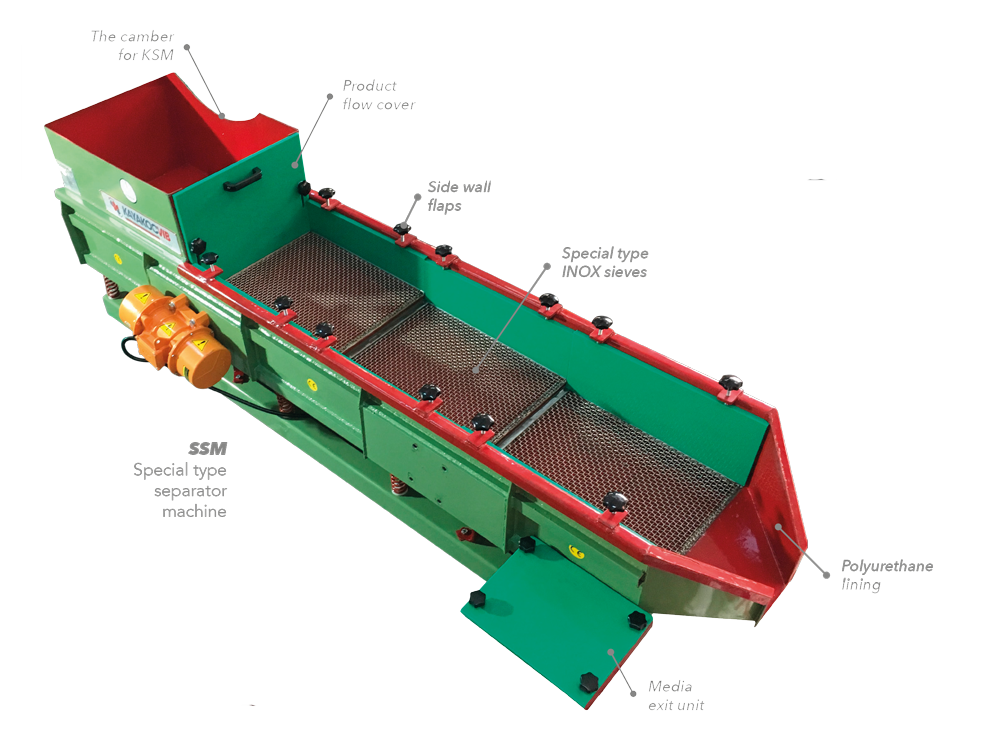

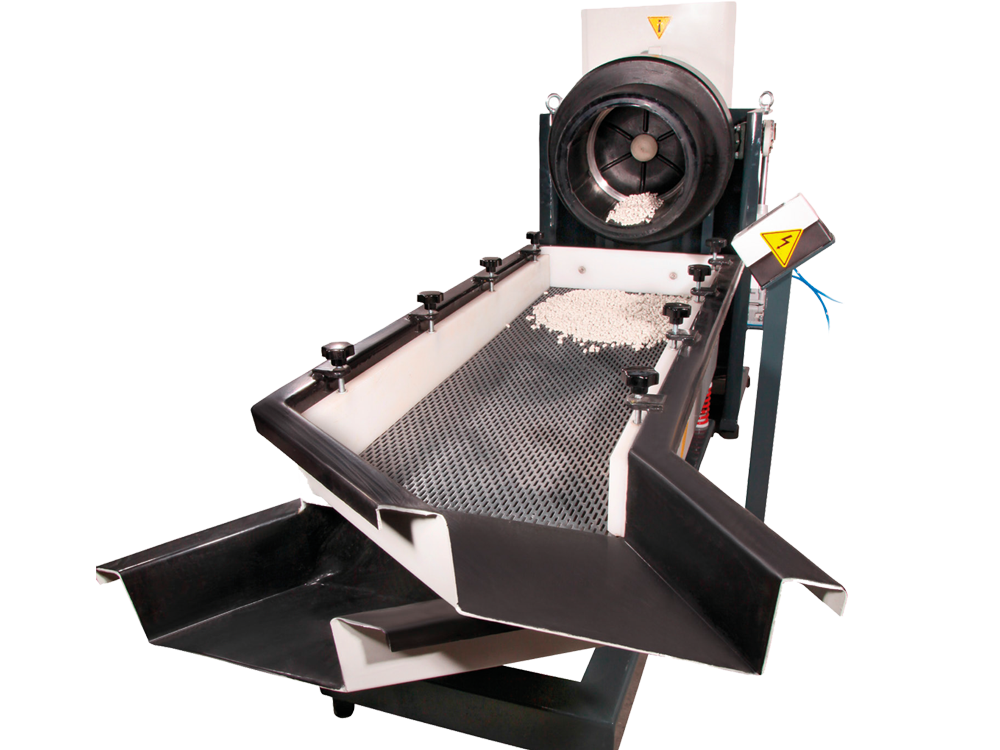

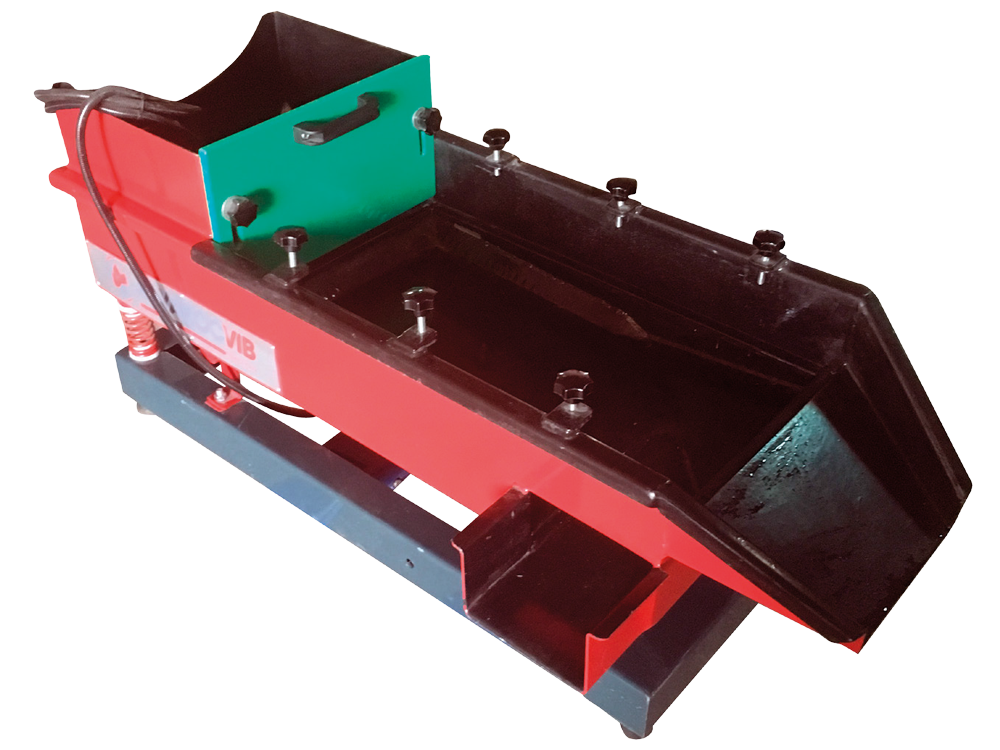

Incorporating cutting-edge technology, the Vibratory Separator Machines of the SM Series, also known as SM coded vibrating screens, seamlessly merge into the innovative KSM series. While the KSM series may not have a dedicated screen, it harnesses the power of SM-coded vibratory separator machines to achieve unparalleled efficiency in chip and product separation.

This advanced integration enhances the overall functionality of the KSM series, making it a versatile solution for various industries. The Vibratory Separator Machines within the SM Series play a pivotal role in streamlining the separation process with precision and effectiveness. These machines excel in efficiently segregating chips and products, showcasing their indispensable value in industrial applications.

Engineered for optimal performance, the SM Series Vibratory Separator Machines within the KSM series offer a seamless and intelligent solution for businesses seeking enhanced separation capabilities. Elevate your operations with the state-of-the-art technology embodied in the SM Series, setting new standards for vibratory separation in the realm of industrial machinery.