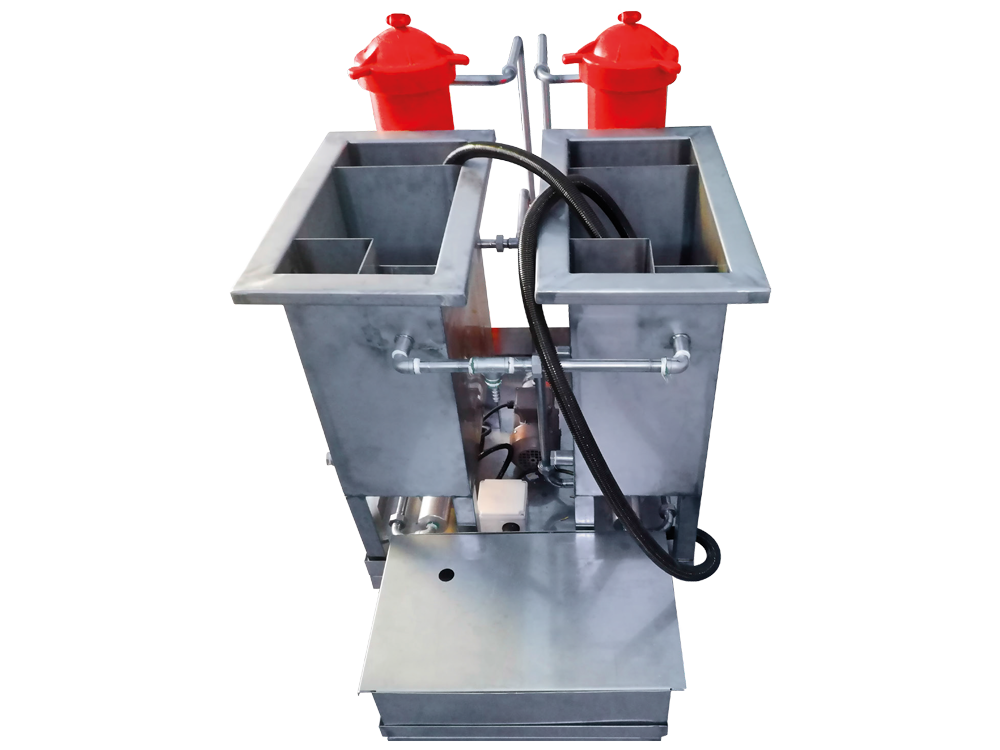

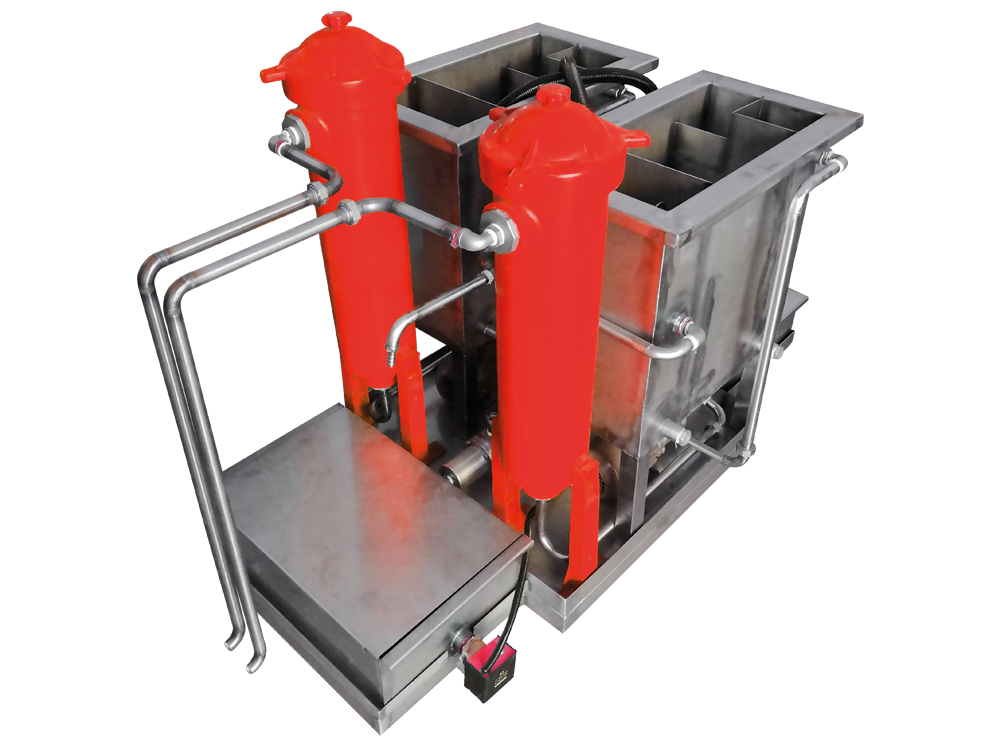

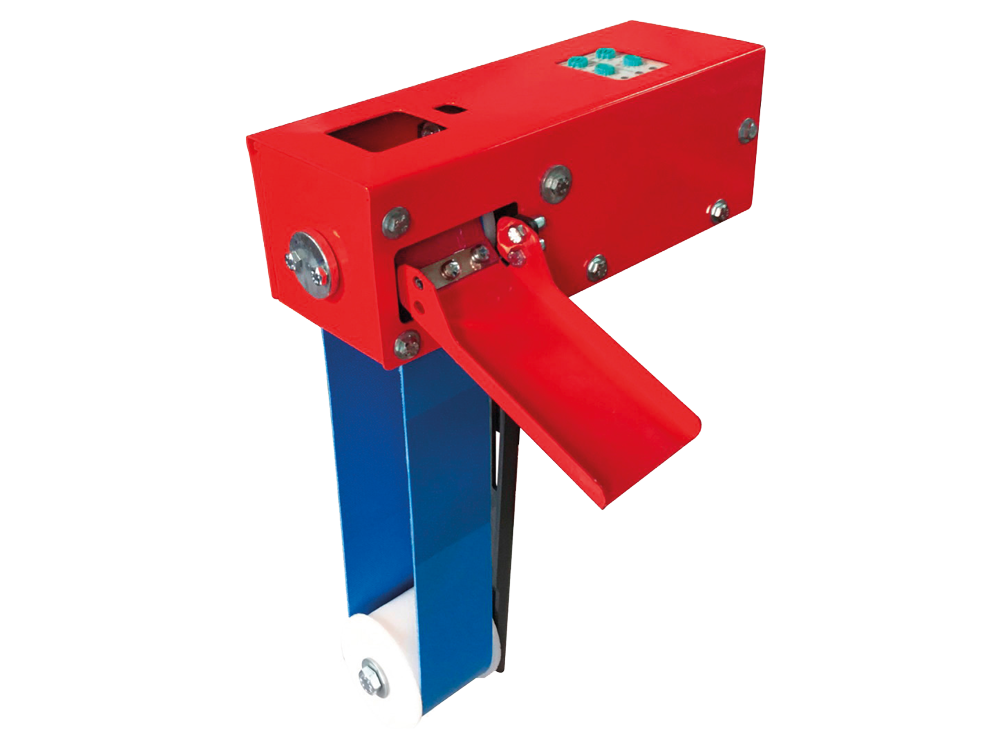

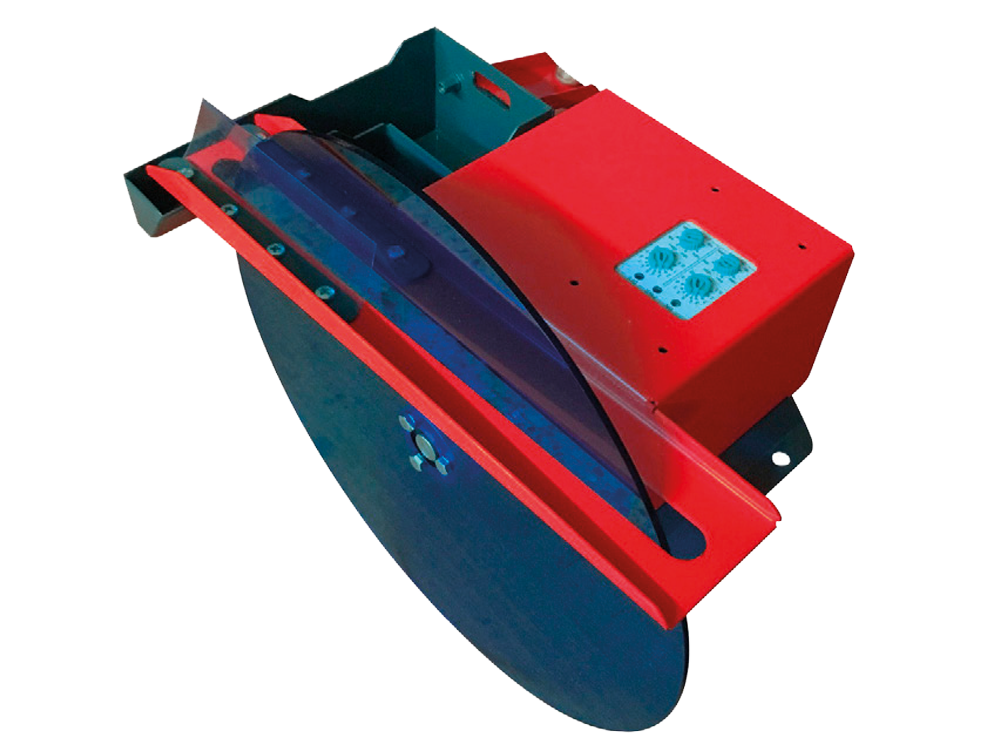

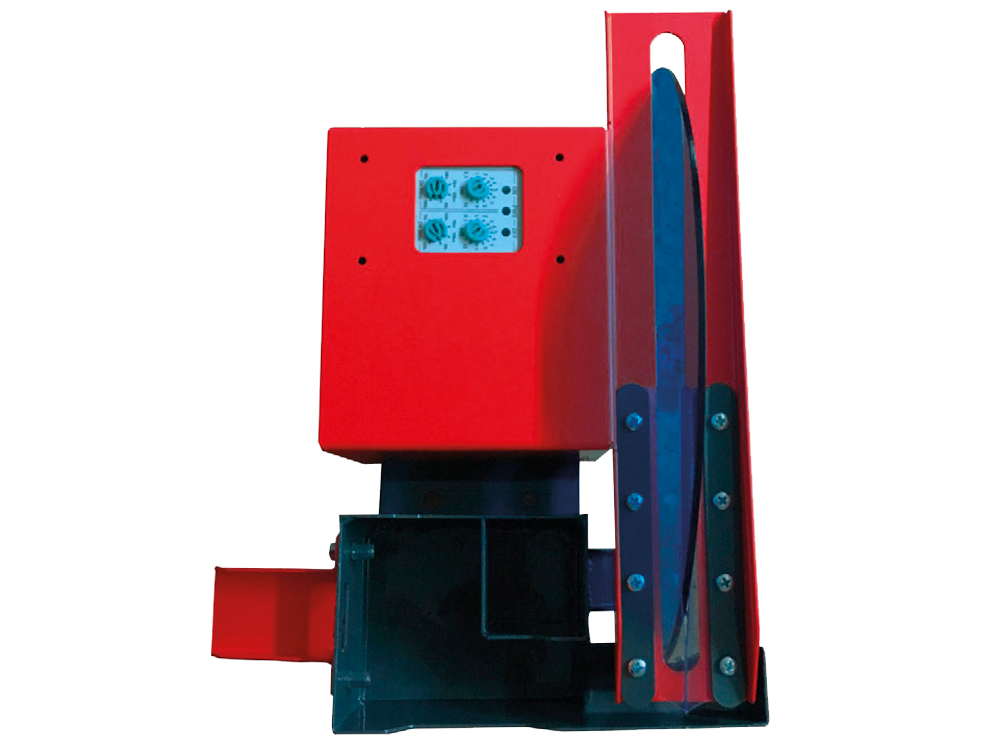

The OIL-S series plays a vital role in efficiently separating unwanted oils from boron oil within metalworking machinery tanks, including CNC, lathe, and milling systems. This innovative solution effectively inhibits bacterial formation in boron oil, significantly extending its lifespan.

By implementing the OIL-S series, businesses can ensure optimal performance and longevity of their metalworking equipment. This cutting-edge technology not only safeguards machinery but also enhances overall operational efficiency. Say goodbye to concerns about oil contamination, as the OIL-S series sets a new standard in the maintenance and preservation of boron oil quality.

Invest in this solution to experience increased productivity, reduced downtime, and cost-effective operations, making it an indispensable asset for the modern metalworking industry. Elevate your machining processes with the OIL-S series, a game-changer in oil separation technology.