PLASTIC CHIPS

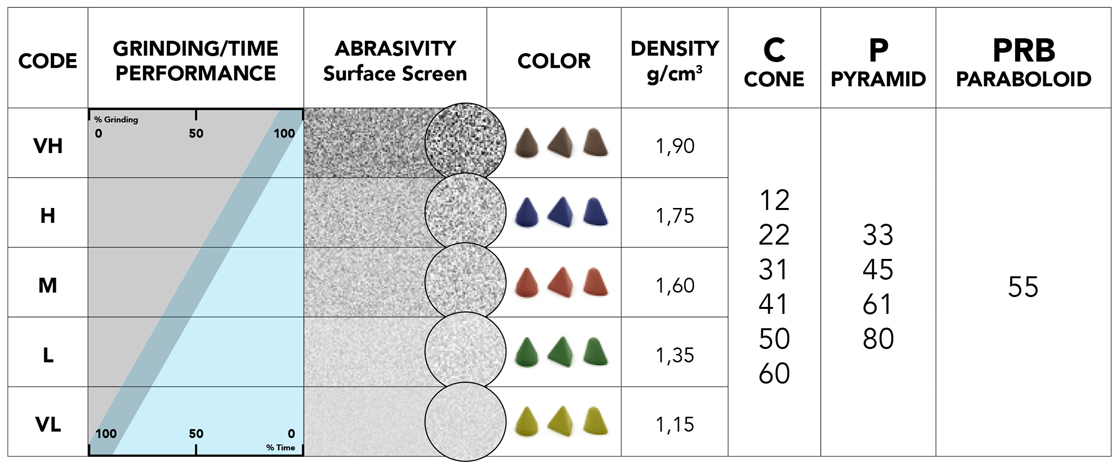

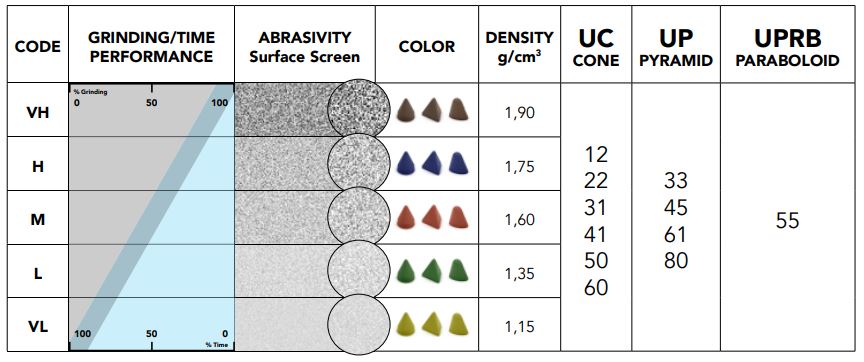

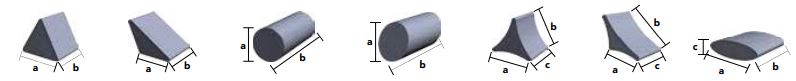

Plastic chips are used for abrasion of sharp corners in non-metal products (copper, zinc-nickel alloys, bronze, aluminum, zamak, composite materials). Our plastic chips are classified and coded as low-medium-high. They have a maximum abrasion-grinding rate. They provide an economic advantage thanks to their long-lasting structure. Our plastic chips can be prepared in various compositions depending on the desired surface quality. Our plastic chips make the surface ready for polishing with the abrasion process and shorten the polishing process.

All the raw materials we use comply with the European standards. We have fully automatic standard production. Please contact us for various geometric chip sizes which are out of the list. Our chips do not leave deposits on metal surfaces. We can make custom production according to your needs. Vibration exit water may contain 1-1.5% solid particles. It is ideal for systems with a treatment unit.