| Covering |

Chemical Composition |

Colour |

Sertlik (HV 0.05) |

Friction coefficient (against steel) |

Thickness (μm) |

Oxidation/ Decomposition Temperature(°C) |

General Characteristics |

Mold Application Suggestions |

|

AlTiCrN |

Dark grey |

3600±400 |

0,4 |

2 – 8 |

900°C |

High hardness, high toughness, good high temperature resistance |

In high pressure aluminum injection cores, aluminum extrusion die-tenon and hot forming cores |

|

AlCrN |

Light grey |

3600±300 |

0,5 |

2 – 5 |

1000°C |

High hardness, high hot hardness, very good high temperature resistance |

High pressure aluminum injection insert-core, in hot forming cores |

|

TiAlN |

Dried rose |

2800±200 |

0,4 |

4 – 8 |

800°C |

High toughness and high hot hardness, low coefficient of friction and high applicability of coating thickness |

In high pressure aluminum and zamak injection cores, pin, insert-core, hot forming cores |

|

ZrN |

Light yellow |

3000±200 |

0,35 |

2 – 5 |

600°C |

Excellent surface properties, very high adhesive wear resistance, very good corrosion resistance |

In high pressure magnesium injection |

FEXOY

|

Diffusion Process + FeO |

Dark black |

1150± 50 |

– |

12 – 15 |

– |

Dark black Abrasion resistance and solid lubricating surface properties Diffusion Process |

Press hot forging dies, Metal injection sleeves |

|

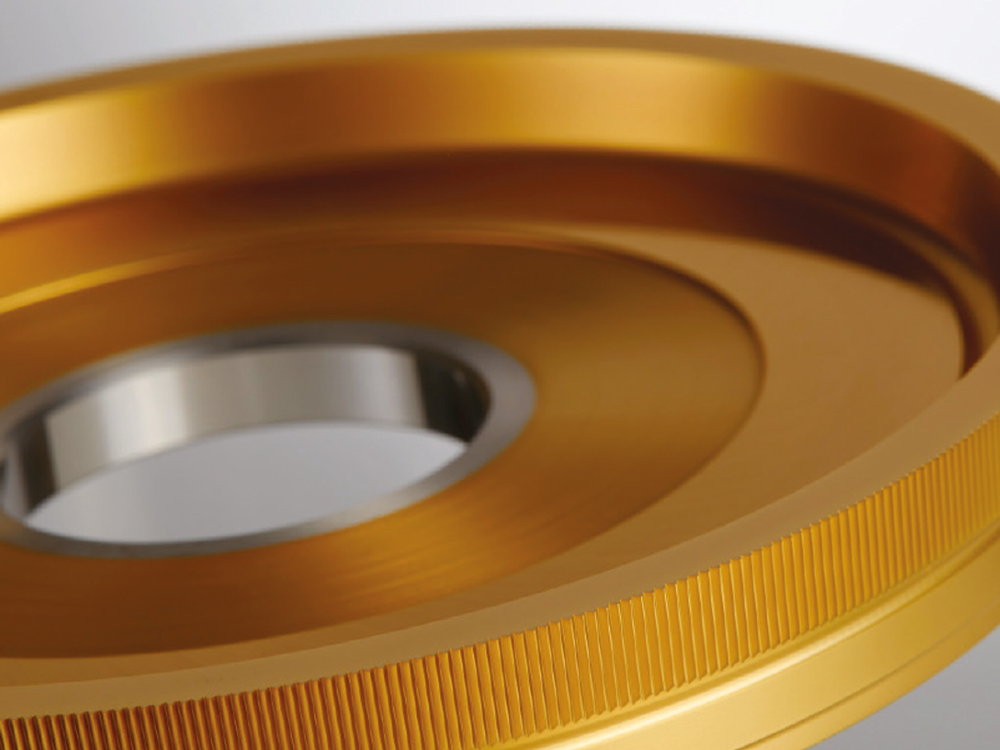

TiN |

Gold yellow |

2600±200 |

0,5 |

2 – 4 |

600°C |

General purpose use, wide application area, all mechanicalchemical properties are moderate |

In cutting (if the workpiece is iron-based) molds |

|

CrN |

Silver grey |

2100±200 |

0,35 |

2 – 8 |

600°C |

High toughness, corrosion resistance, low coefficient of friction |

Forming molds |

|

TiCN |

Magenta-grey |

3800±200 |

0,25 |

2 – 4 |

400°C |

High hardness, high wear resistance and low friction coefficient, improved toughness, lubricating properties |

Cutting, forming molds |

|

TiCrN |

Dark golden yellow |

3400±200 |

0,35 |

2 – 5 |

600°C |

Excellent toughness, low coefficient of friction, high hardness, high resistance to workpiece sticking and wrapping |

Deep drawing, forming molds |

|

AlCrN |

Light grey |

3600±200 |

0,5 |

1 – 4 |

1000°C |

High hardness, high hot hardness, high oxidation resistance |

In cutting (precision, dry cutting) molds |

|

AlTiN |

Anthracite |

3400±200 |

0,75 |

2 – 6 |

900°C |

High hardness, high toughness, high temperature resistance, high hot hardness |

In cutting, plucking cutting, forming mold |

|

ZrN |

Light yellow |

3000±200 |

0,35 |

2 – 5 |

600°C |

Excellent surface properties, very high adhesive wear resistance, very good corrosion resistance. |

Forming (if the workpiece is non-ferrous based) molds |

|

TiN |

Gold yellow |

2600±200 |

0,5 |

2 –4 |

600°C |

General purpose use, wide application area, all mechanicalchemical properties are moderate |

Plastic injection mold, pin, pusher, scrapers |

|

CrN |

Silver grey |

2100±200 |

0,35 |

2 – 8 |

600°C |

High toughness, corrosion resistance, low coefficient of friction |

Plastic injection mold cores, cores, scrapers |

|

TiCN |

Magenta-grey |

3800±200 |

0,25 |

2 – 4 |

400°C |

High hardness, high wear resistance and low friction coefficient,improved toughness, lubricating properties |

Plastic injection moulding, cutting, forming |

|

TiCrN |

Dark golden yellow |

3400±200 |

0,35 |

2 – 5 |

600°C |

Excellent toughness, low coefficient of friction, high hardness, high resistance to workpiece sticking and wrapping |

Plastic injection mold cores, cores, scrapers |

|

AlTiN |

Anthracite |

3400±200 |

0,7 |

2 – 6 |

900°C |

High hardness, high toughness, high temperature resistance, high hot hardness |

Plastic injection mold, cores, pin, pushers, scrapers |

|

ZrN |

Light yellow |

3000±200 |

0,35 |

2 – 5 |

600°C |

Excellent surface properties, very high adhesive wear resistance, very good corrosion resistance, |

Plastic injection mold cores, cores, scrapers |

|

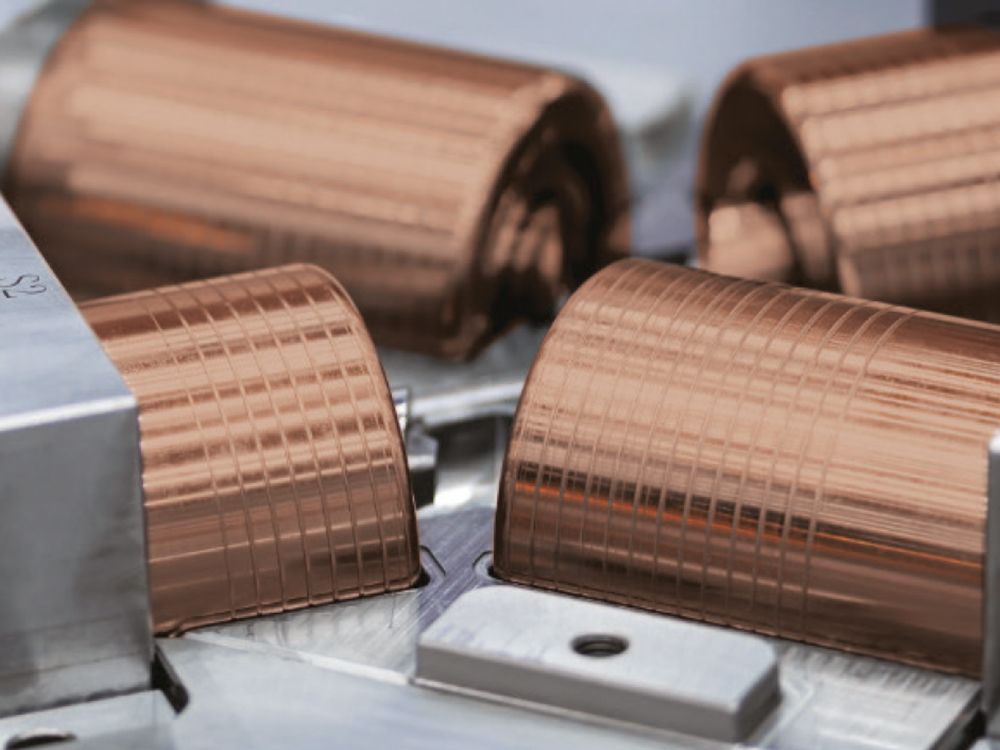

Patent |

Silver gray anthracite |

3400±200 |

0,35 |

2 – 8 |

600°C |

High toughness, corrosion resistance, low internal stress, low coefficient of friction, high wear resistance for copper-beryllium alloy |

CuBe2 – copper-beryllium alloy; plastic injection mold cores, cores |